Globally, an estimated 92 million tonnes of textiles waste is created each year and the equivalent of a rubbish truck full of clothes ends up on landfill sites every second. By 2030, we are expected as a whole to be discarding more than 134 million tonnes of textiles a year. Alarming number according to an article by BBC.

Textile waste is a stream that is still awaiting legislation for separate collection. According to European law, it should come into practice in 2025. Until then, the system is supported by private companies that manage the collection of discarded clothes, and ensure its reuse, recycling, and charity donation.

Managing bins for textile waste

One of the textile waste collection companies fighting against this negative trend is Ekocharita from Slovakia, which was founded only in 2017 and nowadays is already the fastest-growing textile bin operator in the region, with approximately 3.000 tonnes of textile waste collected annually.

Ekocharita operates within an area of 16.000 km2 and manages 1.300 containers for clothes, shoes, toys, and home textiles. The containers are usually distributed in busy urban areas. The availability of textile waste containers in close proximity encourages citizens to sort the clothes properly.

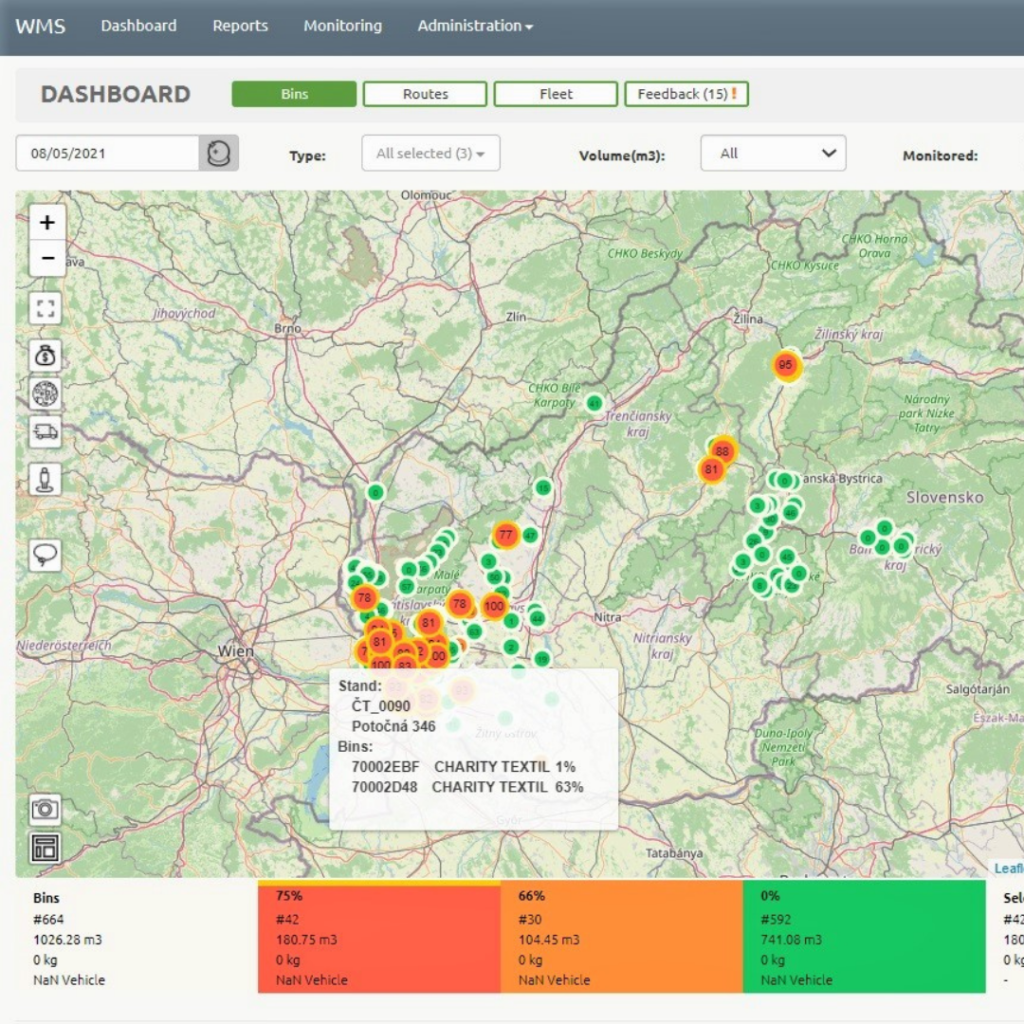

What makes containers for textile waste unique, is their very irregular filling cycles. The speed by which the containers become full is absolutely unpredictable, which makes collecting this waste difficult for operations and logistics and puts high financial and time demands on managers. Real-time online monitoring of fill levels can significantly improve operations and reduce costs.

The textile waste collector started to implement Sensoneo smart sensors to monitor fill levels in containers and facilitate dynamic waste collection. Since January 2021, the company has installed the sensors into 600 containers, digitizing half of the infrastructure.

Smart waste management outcomes

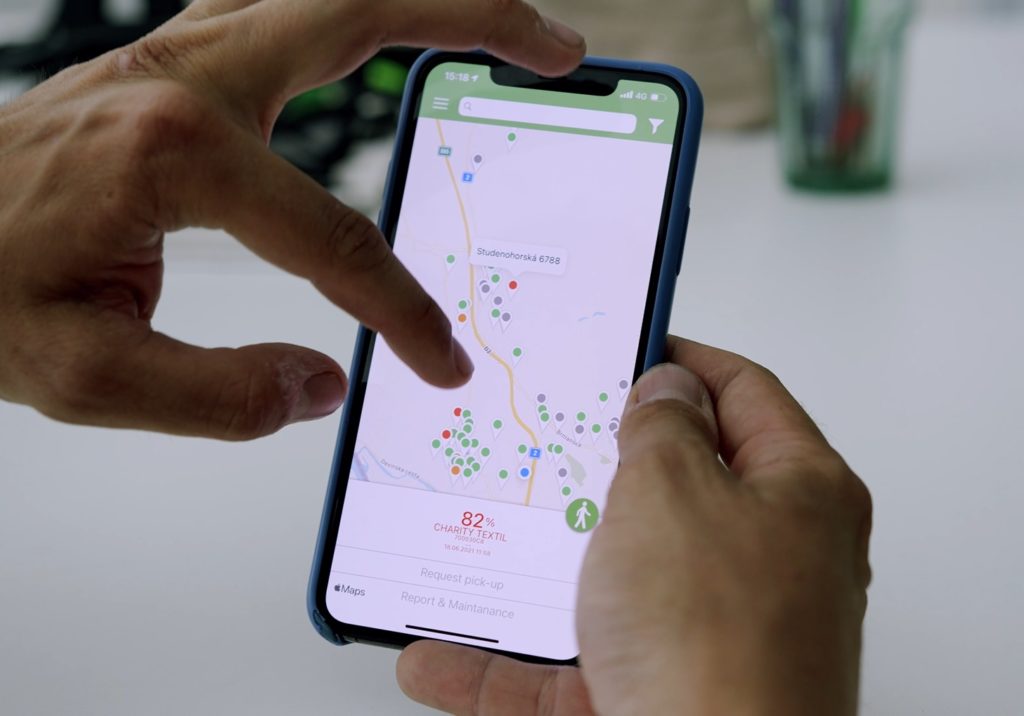

With smart waste monitoring on board, Ekocharita has completely redesigned the way they operate. The whole network is digitalized, and the drivers can easily and quickly identify the containers which really require the pick-up, and so spend their time really efficiently according to Juraj Kunák, founder and CEO of Ekocharita:

„Right now, the driver wakes up in the morning, he opens the app where he sees the orange and the red dots – and that is exactly where he should go to quickly collect the full car – because that is the metrics based on which the drivers are paid. Before the sensors, the collection was based merely on the feelings of the driver: „They were collecting for 8-9 hours to collect the full car. They were running in circles and let’s say in 6 months the drivers were completely burnout. Now they can start at 7 or 8 and can be finished by 12:00 or by 1-2:00 PM and they can go back home to their families. Except of that, it was very ineffective. For example, 5 drivers would come full, but one driver would come empty. Per one day, you can say it does not matter, but after 30 days you are missing let’s say 15 tons inside the warehouse and that is the highest loss. For me, to save transport costs is one thing, but the most important is that I am not losing the material.”

Juraj Kunák, CEO and Founder of Ekocharita

The drivers, originally opposed to the implementation of new technologies, became very proactive as they realized the actual positive effect on their workloads. Juraj Kunak explains: „Even those who said that „I will not use it; I can’t do it with a smartphone“ are the first to open a smartphone at six in the morning, make 12 red dots along the way, and at 10:00 they are back with a full car.“

A huge advantage over competitors

On-time waste collection means avoiding overflowing bins. Potential mess around bins and a dirty environment is a great obstacle for many business partners of Ekocharita:

„Having sensors means being reliable for the partner. That is why we are deploying more and more containers which are very near to us in shopping malls, schools, universities, kindergartens… New areas where I have not been before because there was another competitor. Now we are able to replace them.“

Ekocharita was able to implement the solution thanks to the EIC Accelerator grant that Sensoneo received for large-scale deployment of their solution to prove the positive environmental, operational, and financial benefits of smart waste management. This way, the company could test and experience the actual benefits of a large-scale smart waste management deployment immediately. Naturally, the pace would have been different if the company had purchased the solution the standard way. That is why the company has also calculated the Return of Investment if the investment was fully on them. To calculate the ROI, the company used Sensoneo’s monthly „smart waste as a service“ pricing. „If the purchase of the sensors had been fully on us, we would have received the ROI in 7 months,“ explains Juraj Kunak, CEO and Founder of Ekocharita.

Thanks to data from the sensors, the company has managed to significantly improve the management of its operations as they

- decreased the time required for the collection of 1 tonne of textile waste by 30 percent,

- reduced the waste collection cost by 20 percent,

- made the logistics process smoother and better organized,

- and gained a significant advantage over competitors.